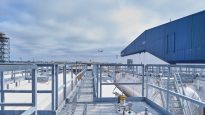

South Deicing Complex Support Facilities

South Deicing Complex

Atlanta, Georgia

The award-winning South Deicing Complex Support Facility at Hartsfield Jackson Atlanta International Airport maximizes aircraft operations during winter weather. This facility provides glycol and fueling delivery, worker comfort accommodations, a six-bay truck maintenance area, and a control room. Type I and Type IV glycol, gasoline, diesel, and DEF are stored at the site’s south side and are pumped to dispensers with the capacity to service up to ten trucks within a steel canopy. The storage tanks for each fluid consist of four 65,000-gallon Type I Glycol tanks, two 40,000-gallon Type IV glycol Tanks, two 20,000-gallon gasoline tanks, two 20,000-gallon diesel tanks, and one 3,000-gallon DEF tank. The glycol is delivered via four pumps mounted within a second steel canopy on the west side of the site. Access and egress from the roadway to the delivery canopy and underground tanks are controlled by two 50-foot slider gates and security fencing. Delivery and dispensing operations are maintained within the control room inside the building. Eleven cameras mounted atop an 80-foot concrete pole monitor the South Deicing Complex Support Facilities and deicing pads. The 11,000-square-foot building houses worker comfort facilities consisting of a breakroom, kitchenette, four showers, three toilets divided between men’s and women’s restrooms, laundry facilities, and 168 lockers. The truck maintenance bay contains six bays, five insulated roll-up doors, six hose bibs, and six compressed air hose connections. Sixteen display workstations access the eleven cameras previously mentioned to monitor the Delta Avtec system and facility, fuel, and glycol operations. Manhattan completed the work at the South Deicing Complex Support Facilities without disrupting the airport field operations surrounding the worksite.